Bucket elevators are continuous conveyors that can elevate material vertically from low to high place and use a series of hoppers evenly attached to the chain or belt to transport the bulk material vertically.

Bucket elevator

Bucket elevators are continuous conveyors that can elevate material vertically from low to high place and use a series of hoppers evenly attached to the chain or belt to transport the bulk material vertically. Bucket elevator used for powder, granular, and small pieces of material delivery. After the material being put into the hopper through the material inlet, the machine automatically runs up continuously. When the conveyor belt or chain is lifted to the top, the material is poured into the receiving groove.

According to the different characteristics and usage of the equipment, there are three types of TH chain bucket elevator, NE chain bucket elevator and TD ring belt elevator.

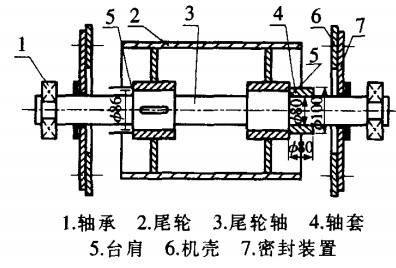

In order to solve the situation of dust escaping in gypsum powder production, the bucket elevator tail wheel produced by our company is equipped with sealing devices, as shown in the diagram below:

1. Bearing; 2. The tail wheel; 3. Tailwheel shaft; 4. Collar; 5. Shoulder; 6. The casing; 7. Sealing device;

The sealing device consists of dust jacket, asbestos rope and dust cover, which can effectively prevent dust channeling out.

1) Chain bucket elevator

Ring chain bucket, hopper, chain through the bucket hook connected together, forming a ring, driven by the head wheel, hopper upward movement. Ring chain bucket elevator adopts mixed or gravity unloading, digging type charging. The chain is made of high quality alloy steel.

Main features:

Conveying material temperature up to 250ºC.

Lifting height runs smoothly and reliably.

The lifting throughput of the improved model is more than 30% higher than that of the ordinary model.

The hoist ring chain is forged by low alloy steel and treated by carburizing and quenching, with high tensile strength and wear resistance.

The equipment has simple structure and low cost.

Excavating material type design, more flexible layout.

2) Plate chain bucket elevator

Plate chain bucket elevator, the use of plate chain and hopper connected to form a ring, driven by the first wheel, lifting materials; It adopts inflow feeding, induced unloading and large capacity hopper intensive arrangement, and there is almost no material return and digging phenomenon during material lifting, and extrusion and collision phenomenon rarely occur between materials.

Main features:

Less mechanical wear, long service life.

Reliable operation, good sealing, low noise.

Good sealing performance, less environmental pollution.

Low driving power, more energy saving.

Convenient operation and maintenance, less wearing parts.

Due to less energy saving and maintenance, the use of low cost.

After folding and middle reinforcement, and then welding, good rigidity, beautiful appearance.

3) Belt bucket elevator

Belt bucket lift, the principle and TH bucket lift similar, the use of transmission belt.

Reliable operation, low noise.

The equipment has simple structure and low cost.

Excavating material type design, more flexible layout.

Main features:

Less mechanical wear, long service life.

Reliable operation, good sealing, low noise.

Good sealing performance, less environmental pollution.

Low driving power, more energy saving.

Convenient operation and maintenance, less wearing parts.

Due to less energy saving and maintenance, the use of low cost.

After folding and middle reinforcement, and then welding, good rigidity, beautiful appearance.

Processing demand survey

x